Worldwide Flight Services (WFS) is helping Brussels Airport expedite the processing of trucks carrying import and export cargo by becoming one of the launch partners for the new BRUcloud Slot Booking App.

Launched on 15 January 2018, WFS has allocated dedicated cargo doors for customers booking freight collections or deliveries using the new app. Other companies participating in the launch include DHL Global Forwarding, Nippon Express Belgium, Kuehne + Nagel, and Panalpina.

WFS helped to test the new app in September 2017 when it joined forces with DHL Global Forwarding and Nippon Express in a trial in which all freight deliveries and pick-ups from its warehouse buildings 709 and 712 at Brussels Airport were booked using the Slot Booking App between the hours of 08.00-22.00rs.

The app aims to speed up cargo handling at the airport by matching requests for truck loading and unloading with the time slots made available by ground handlers and proposes an alternative slot if no match can be found.

Marc Claesen, Regional Vice President of WFS in Belgium, said: “At WFS, we are always looking for ways to improve service levels for our airline customers and their freight forwarding partners. We, therefore, applaud and were keen to support Brussels Airport’s initiative to launch the BRUcloud Slot Booking App. Based on the trials we conducted last year and our experience since the app went live last month, we can see it offers a smart solution to significantly reducing truck waiting times for freight forwarders at BRUcargo. With customers becoming more confident in using the app, we can see this leading to further technologybased solutions at the airport, which will benefit all parties.”

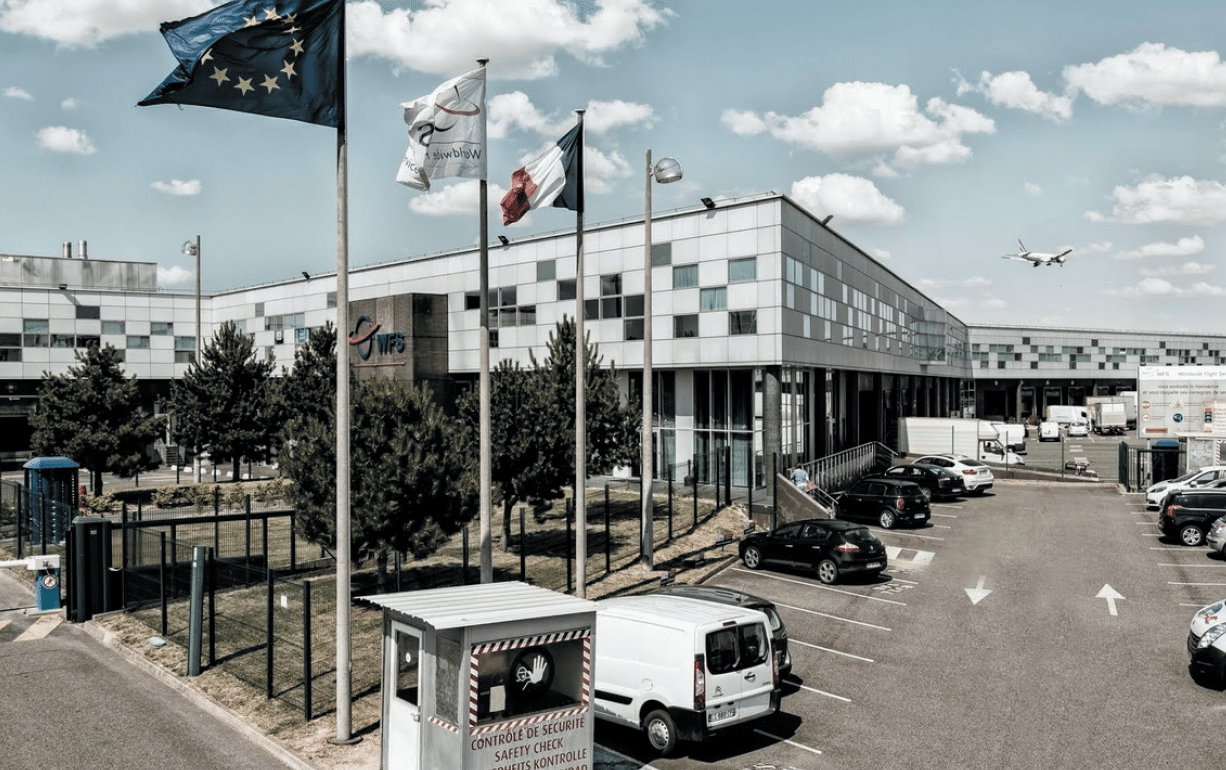

This is the latest customer benefit delivered by WFS in Belgium. Last December, Brussels also became the first of Worldwide Flight Services’ (WFS) European cargo stations to achieve IATA CEIV Pharma certification to manage its customers’ growing pharma volumes, WFS has installed two new dedicated pharma cells in its main warehouse in Brussels to help maintain the integrity of pharma products within 15-25°C and 2-8°C temperature-controlled environments. As part of its successful CEIV certification programme, it has also adopted specific pharma handling procedures and provided training for its staff working in the upgraded facility.

-ends