Worldwide Flight Services’ (WFS) Pharma Centre at Paris Charles de Gaulle Airport has been awarded Good Distribution Practice (GDP) certification, reinforcing its credentials to support global air cargo shipments of Covid-19 vaccines and other pharmaceutical and medical equipment shipments requiring compliant temperature-controlled storage and handling.

At the start of 2020, the Centre, part of a multi-million Euro investment by WFS in global pharmaceutical handling facilities, also achieved IATA CEIV Pharma certification.

The GDP audit and certification process by independent auditing specialists TÜV confirmed the facility’s temperature management capabilities and assessed and approved WFS’ pharma policy, including its internal auditing procedures, risk assessment and corrective/preventive measures, and critical supplier list.

Yann Favre, newly-appointed Manager Pharma at the WFS Center in Paris, said: “As the world’s largest air cargo handler, WFS is already very actively involved in the safe and compliant handling of pharmaceutical shipments and medical devices across our international network. Gaining certifications for both IATA CEIV and GDP for our Pharma Centre in Paris means we have achieved the highest respective global standards recognised by the air cargo and pharmaceutical industries. This supports our objective to be the world’s leading air cargo handler for pharma shipments in terms of compliance and our able to safeguard product integrity.”

WFS’ trained and accredited team of pharma specialists at Paris CDG also use the company’s fleet of temperature-control trucks, trailer and dollies to ensure the efficacy of pharma cargoes from aircraft to warehouse and vice versa.

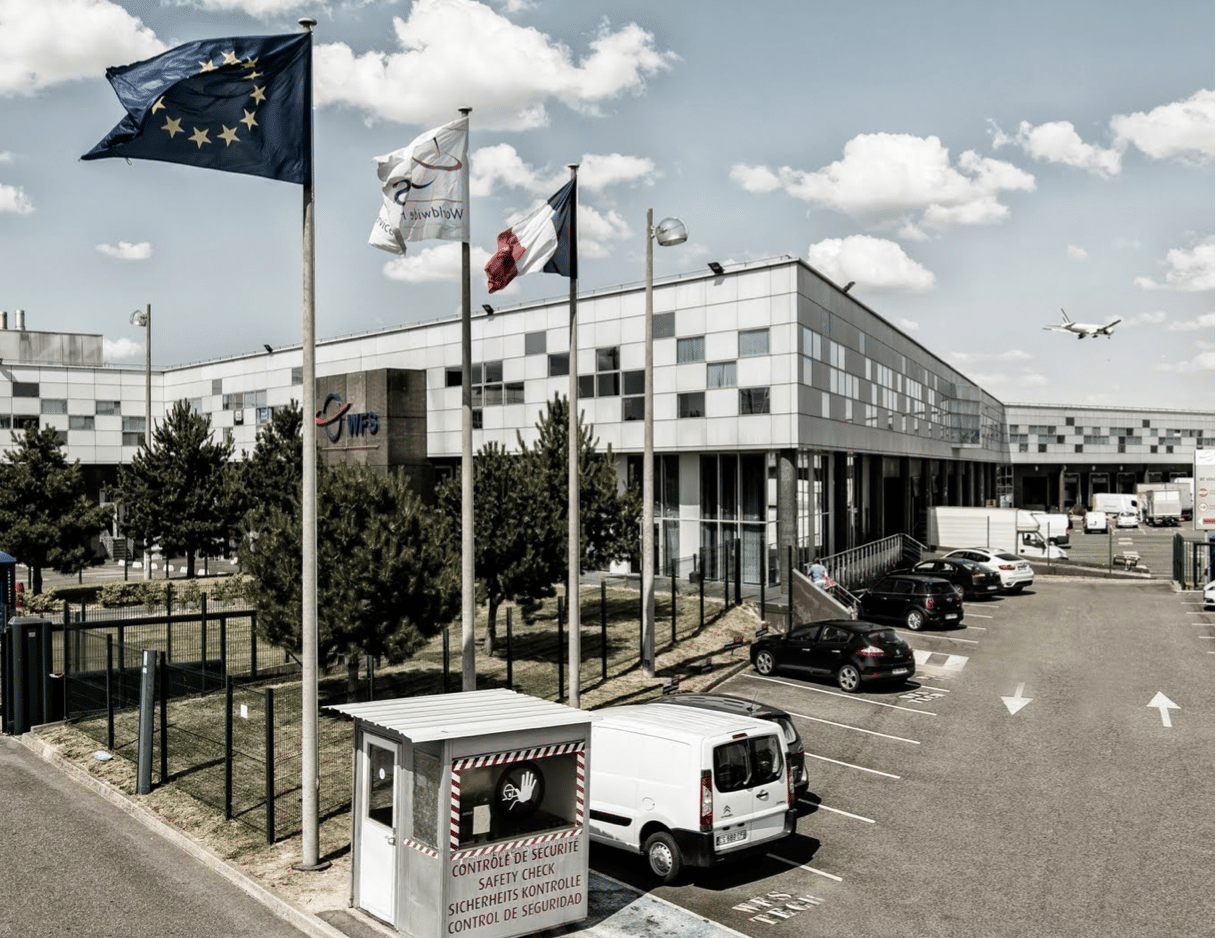

As the only dedicated pharma handling facility owned by a ground handler at Paris Charles de Gaulle (CDG), the Centre already handles over 8,000 tonnes of temperature-controlled shipments a year for nearly 40 airline customers. WFS expects the Center to play an important role in the handling and distribution of Covid-19 vaccines for the population of France once these shipments begin.

Situated in the heart of the airport’s cargo area, the 2,400m² Pharma Centre provides landside and airside acceptance capabilities and distinct temperature-controlled storage areas. The dedicated operation has its own docks and maneuvering area for the loading and unloading of temperature-controlled pharmaceutical shipments and incorporates:

- a dedicated room for loose cargo storage at +15 to +25°C with a capacity for 108 euro-pallets on four levels of racking.

- a separate cold room for loose cargo storage at +2 to +8°C with the capacity to store 47 euro-pallets on the ground, and with additional racking also available.

- a freezing room for loose cargo storage at -20°C capable of handling 9 euro-pallets at a time.

- two temperature-controlled areas for +2 to +25°C for cargo unit load devices with a combined capacity to store 53 P2P or 106 AKE pallets.

Last month, WFS announced the creation of a special Project Coldstream task force to safely and securely coordinate and manage its global response for the 16 billion doses of Covid vaccines expected to be transported by air cargo services. In addition to Paris CDG, WFS also operates pharma facilities in Amsterdam, Barcelona, Brussels, Cape Town, Copenhagen, Cork, Dublin, Frankfurt, Johannesburg, London, Madrid, Miami, and New York JFK, which are either IATA CEIV or GDP certified or compliant.

Customers using this international network of pharma facilities have access to:

- Dedicated facilities in the heart of airport cargo zones to expedite handling of imports and exports

- Solutions for pharma shipments requiring both +2°C to +8°C and +15°C to +25°C temperature environments, and -20°C in some of stations

- Real-time temperature monitoring and temperature excursion alarms

- Full track and trace capabilities

- Active temperature-controlled container handling

- Temperature-controlled trucks, trailers and dollies

- Landside and airside acceptance

-ends-